Project summary

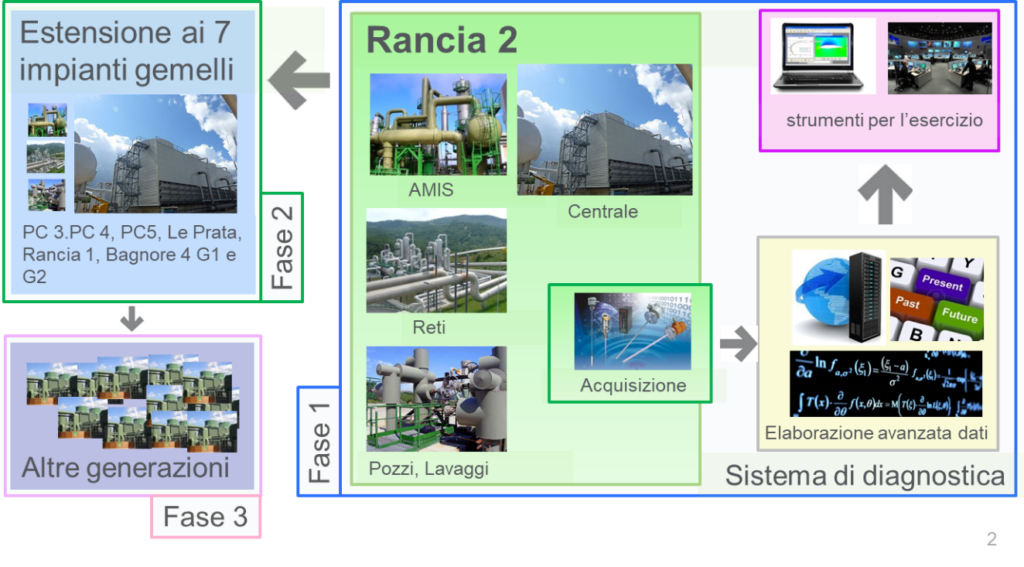

The SmartGeo project aims to prototype, develop and put into service advanced and innovative technological solutions on the «Rancia 2» Geothermal Plant and on the structures connected to it (wells, steam networks, steam washing systems, reinjection, Amis).

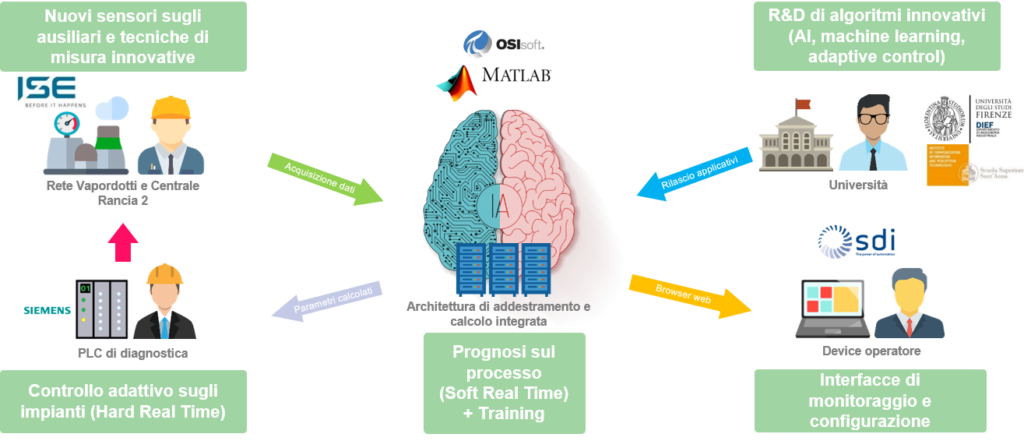

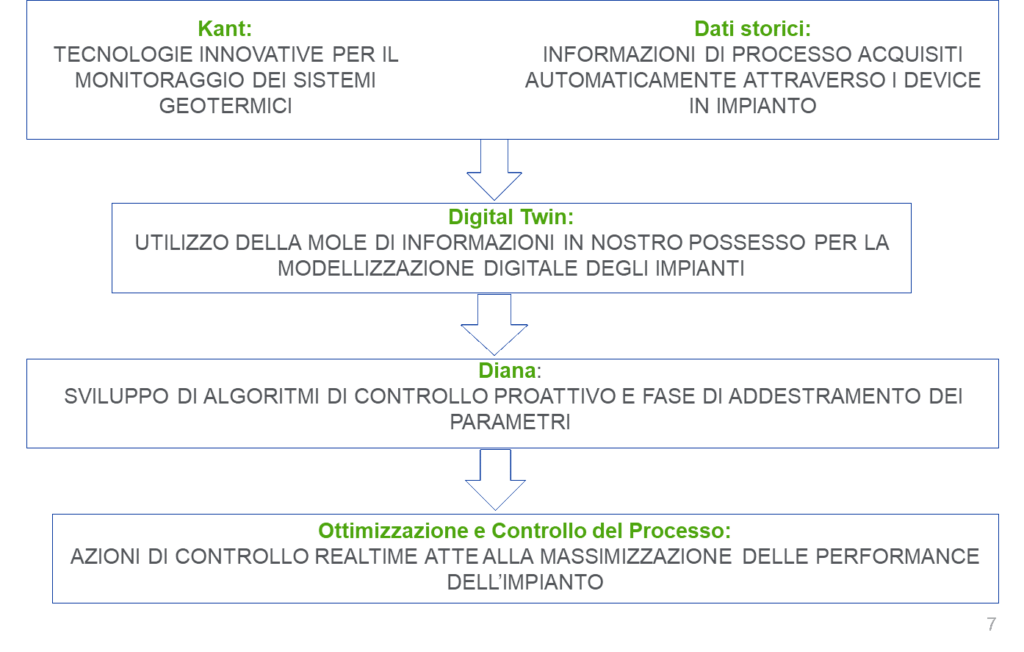

Below is the flow of project development: from data acquisition to their use in the control and monitoring of the production process.

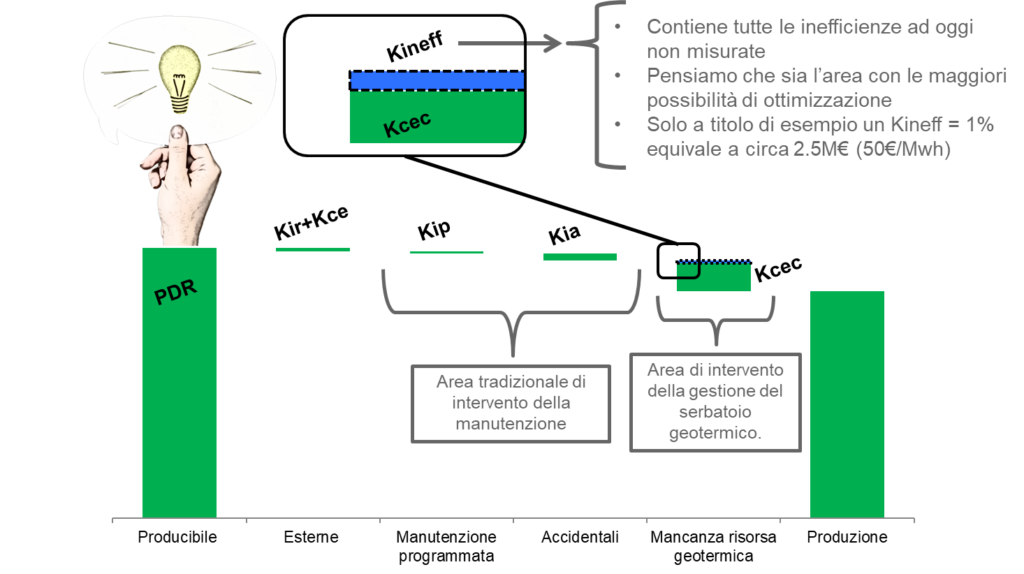

Indeed, it is possible to further improve the efficiency of geothermal plants by minimizing inefficiencies and unplanned events.

The area of the Kcec geothermal reservoir includes, in unknown quantities, all the causes of inefficiency that cannot be measured to date.

Targets

Prototyping, development and commissioning of advanced and innovative technological solutions of prognostics, artificial intelligence, machine learning and control in the “Rancia 2” geothermal plant and on the structures connected to it (wells, steam vans, steam cleaning systems)

- Increase auxiliary monitoring by installing innovative and traditional sensors

- Predictive maintenance on components thanks to statistical prognostic analysis

- Increase the production efficiency of the prototype through an adaptive control based on artificial intelligence and machine learning techniques

- Creation of an integrated and usable platform (data scientists, universities) for the development and commissioning of innovative analysis and control algorithms (mathematics, physics, statistics)

Real-time monitoring with advanced analysis tools helps:

- Avoid drowning wells

- Avoid network losses

The KIA + KIP area of intervention is one in which, historically, O&M Geotermia has focused more on optimizations.

However, advanced prognostic tools allow for further improvement:

- Optimize planned stops even more

- Diagnose component deterioration

- Predict breaks

- Prevent unplanned blocks

As a pilot plant, a new generation 20MWe group was chosen, located in the municipality of Radicondoli (SI): the objective in practice translates into an increase in annual production of around 1,500,000 kWh from renewable sources.

We believe we can achieve this goal by avoiding both plant downtime due to failure and reductions in yield.

The recovery of plant productivity is linked to the adoption of new diagnostic and prognostic tools that will allow the reduction of downtime for maintenance. They will foresee the occurrence of failures at least 20% earlier than the current situation.

The developed system, using implemented advanced sensors, will allow a better diagnostics on the operating status of parts of the plant (false alarms reduced by at least 15%) leading to an increase in the plant operating time in optimal conditions of at least 20 %.

Project phases

The phases of the project can be summarized in three main steps, the prototyping (SmartGEO), the extension of the solutions to the 7 twin plants, the extension to all the other types of plants.

The operating flow of development of the SmartGEO project was to start from the base of the data acquired by the plants, data used then to go to build digital structures representing the physical ones, the so-called digital twin. Thanks to these digital representations it was then possible to develop a whole series of technical / algorithmic solutions aimed primarily at monitoring, prognostics and the control of our pilot plant and the systems connected to it.

Now let’s look at the various operational activities of the SmartGEO project in more detail.